TFM SRL

Menu principale:

AUTOMATIC

MANUFACTURING FACILITY > WASHING DRAFT

AUTOMATIC WASHING

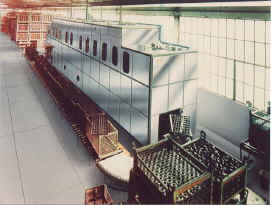

AUTOMATIC WASHING SYSTEM MOD. "MLDQ-C"

Built for the washing of motor vehicles, agricultural motors.

Fully automatic, automatically enters the basket from the loading area and meet all the treatment in the tank to dive with continuous rotation of the basket.

Basket size: 1200 x 600 x 600 h mm.

Weight load: 800 Kg

Treatment cycle:

Dry immersion with agitation.

rinse immersion.

Passivation dipping.

Drying with hot air.

Cycle time 30 minutes

Production capacity 1 basket every 10 minutes

PLANT FOR AUTOMATIC WASHING MACHINE MOD. "MLDQ/6S"

The plant was designed for cleaning small parts, in particular taps.

The equipment consists of nr. 4 cleaning stations:

- Dry immersion (double)

- Rinse

- Rinse hot

- Drying.

The pieces are placed in baskets standart size of 450 x 300 x 220 h mm.

Each basket can weigh about 20 kg

The system automatically loads two baskets at a time.

The baskets are running throughout the course of treatment to.

The baskets through a separate system, each station in turn.

At the end of the cycle parts are. defatted, perfectly detruciolati and dry.

The production of this plant, is 2 baskets every 3 to 4 minutes

PLANT FOR AUTOMATIC WASHING MACHINE MOD. "MLDQ-4S-C"

Built for the particular type of small metal washing.

The pieces are placed in perforated baskets standart (450 x 300 x 220 h mm).

ACILITIES the charge from a lung two baskets at a time, on a robot handling.

The robot runs the course of treatment.

must rotate the baskets that have a lid placed on the operator.

The machine automatically reads the lids and then controls the rotation of the baskets.

Unloading of the baskets is automatic.

Treatment cycle:

- Immersion in degreasing solution.

- Rinse

- Rinse

- Drying with hot air.

Total cycle time of 30 minutes.

Productivity 2 baskets per 30 mimnuti

Max weight 20 kg per basket.

MULTISTAGE MACHINE MOD. "MLDQ"

Built for washing engine sports car.

Cycle Washing:

- Washing with agitation and ultrasound.

- Rinse.

- Drying.

The basket inside a special rotazioone to increase the evacuation of dirt and waste processing.

It has a fully automatic cycle.